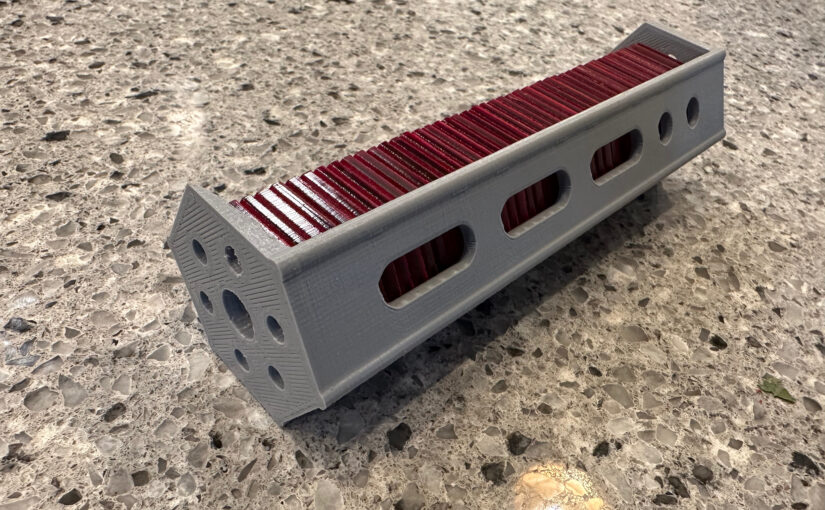

The “poker chip” rack of hexagonal Sabacc chips went through several revisions before becoming the refined version you saw in a previous post.

Category: MakerBot

My Sabacc Credit Chip Evolution

This is one in a series of blog posts about Sabacc: When Christine and I first learned to play Sabacc, it was on the Galactic Starcruiser. Betting was done with little plastic chips, about the size of a dime. After departing, we played in our hotel room — using torn up scraps of paper as … Continue reading My Sabacc Credit Chip Evolution

3D-Printed Droid Bobbleheads

I remixed some Star Wars droid bobbleheads for use on the car dashboard.

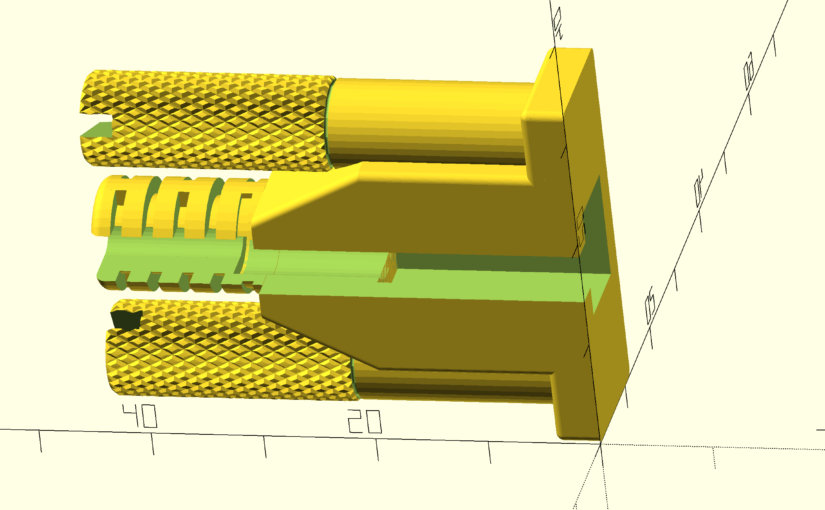

Remaking the Fake VGA Charge Cable

“Is that a VGA cable plugged into your phone??” Designing and printing a fake VGA charge cable.

Wear Your Result on Your Sleeve, errr, Chest

So. We’re returning to “normal life” now. Or at least, we’re trudging ahead, seeking out the new normal. By now, most of the US has dropped mask mandates (excluding public transit and hospitals). Everybody who is not a conspiracy theorist has been vaccinated and boosted. We can get a small ration of free at-home test … Continue reading Wear Your Result on Your Sleeve, errr, Chest

The Award for Best Oscar Party Goes To…

I have a friend who’s been hosting Oscar parties for as long as I remember. They’re always big ordeals, with acceptance speech bingo and a predictions guessing game — both with prizes. A few years ago I downloaded a 3D model of the Oscar from Thingiverse¹. The 3D printer I had at the time just … Continue reading The Award for Best Oscar Party Goes To…

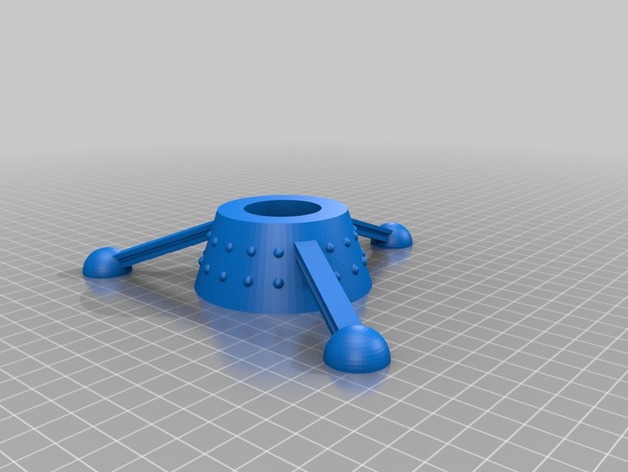

Dalek/Lander Toothbrush Stand

As a Christmas present to myself, I picked up a new 3D printer. The old MakerBot Replicator — so old it’s wooden-framed — has been getting long in the tooth. Its reliability wasn’t outstanding to begin with, but has sunk even further over the years. The year has been good to me, so I decided … Continue reading Dalek/Lander Toothbrush Stand

My work, on display at NAB

It’s not unusual for a product or service that I played some small part in designing and building to appear at an industry trade show, whether that’s CES or NAB or whathaveyou. But this year, a device in which I was a lot more integral in the hands-on design and manufacture appeared. I not only designed a … Continue reading My work, on display at NAB

On equality, with a digression into toys

I am going to get serious for a few paragraphs, but don’t worry. It will lighten up and there will be cats. Today, in the United States, is Martin Luther King Jr. Day. It is a federal holiday celebrating the life and work of MLK Jr. The world has changed significantly since the 60s — … Continue reading On equality, with a digression into toys

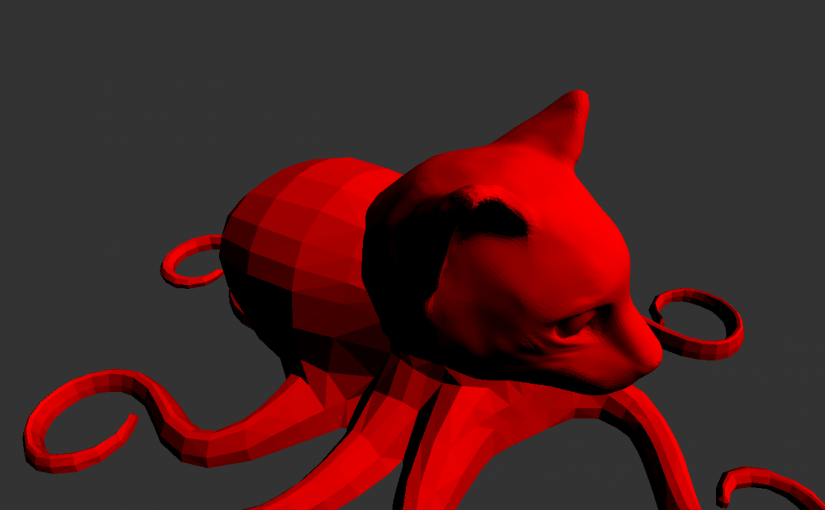

Further adventures in OpenGL: Octocat

As a followup from my previous OpenGL post: I have now successfully rendered an external STL file (a 3D printer object) using OpenGL. And what better model than the Octocat? Warning: nerd talk ahead. Stop reading if you don’t care about the nerdy details. It turns out that I can’t de-dupe the points as I … Continue reading Further adventures in OpenGL: Octocat